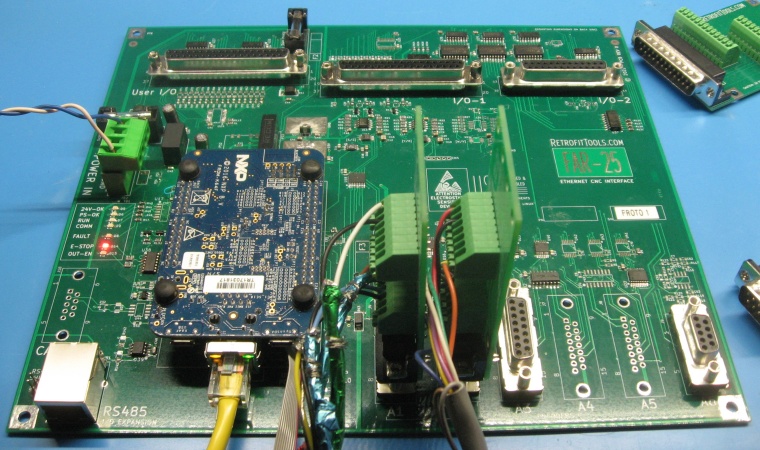

Jan 2024 — We are back working on FAR-25. We did some beta testing on a machine last year; results are promising. We hope to do more soon. The new Dragon GUI is so impressive!

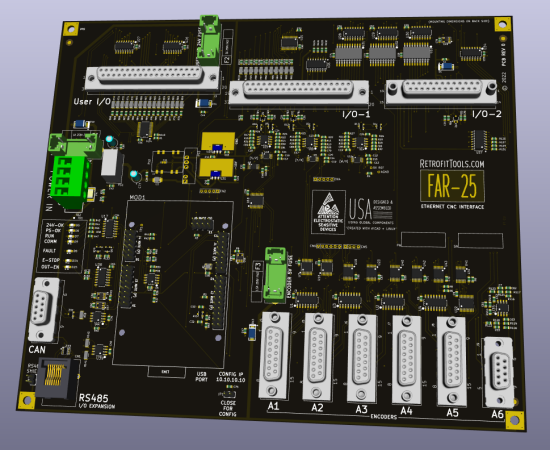

FAR-25 can be used as a general purpose CNC interface, but it also plugs directly in place of obsolete Fagor 8025 and 8030 controls. Form factor and connectors have been chosen to require few if any changes to hardware when migrating from these old controllers.

We have two 3-axis machines where we will be testing the FAR-25.

FAR-25 will:

- directly plug in place of Fagor 8025 and 8030 controllers

- replace aging I/O with solid-state components with high durability

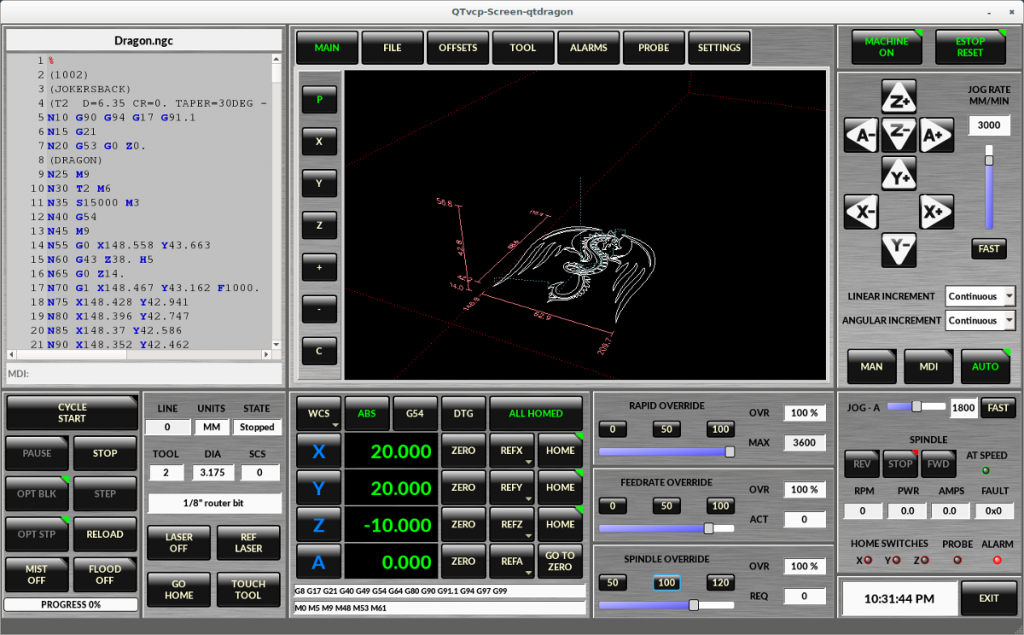

- replace failing monochrome CRT display with a standard PC and modern LCD

- connect via Ethernet (100base-T twisted pair) to a PC running LinuxCNC control and user-interface software

- replace the limited computing power of the 8025/8030 with a multi-core 64-bit PC running LinuxCNC

- add a new User I/O interface with an additional 16 inputs and 16 outputs, which can implement PLC logic in LinuxCNC (PLC programming necessary)

- support economical expansion boards to add I/O points

Imagine the improvement!

Replace the tired old CRT with a modern PC and LCD and just a few of the things you will gain…

- Full color graphics

- Full screen text editing

- Toolpath visualization

- Logical cut/copy/paste

- Modern file manipulation

- Virtually limitless file size and storage

- Access to USB drives

- Touchscreen support

- Full keyboard and mouse/trackball

Retrofitting?

Let’s face it… retrofit wiring time is expensive and tedious!

- If you are retrofitting a Fagor 8025 machine, FAR-25 will save you a ton of wiring and debugging time.

- Gives you a cost-effective and high-reliability I/O solution.

- Makes integration into LinuxCNC as simple as editing configuration files to set physical characteristics and link signals

Easier wiring!

- New -PT breakout boards allow solderless connection to I/O

- DSUB 9, DSUB 15, DSUB 25, DSUB 37 versions

- High-quality ‘Phoenix Contact’ spring terminal blocks

- DSUB 9 with optional differential to single-ended conversion for FAR-25 spindle application

- Easily remote-mounted using ribbon cables

FAR-25 offers:

- Up to 5 (analog velocity) axes PLUS spindle, all 16 bit resolution

- Up to 6 Quadrature Encoder inputs for axes plus spindle

(differential A/B/Z, single-ended A/B/Z for spindle) - MPG Quadrature Encoder A/B input (in place of one axis)

- ‘Standard’ 11 inputs and 32 outputs

match Fagor 8025 IO-1 and IO-2 connectors - Added 16 digital inputs and 16 digital outputs for 24Vdc

(sinking inputs and sinking outputs) - Probe Input supports 5 and 24 volt probe signals

- ESD protection on ALL signal inputs and outputs

- Fuse or polyfuse protection of all power signals

- RS485 Expansion port

- CAN Expansion port for future applications

FAR-25 requires:

- 24V dc power supply, at least 2 amps

- a dedicated 10/100baseT Ethernet connection (network must be insular and is to be dedicated to control of one machine)

- a user-supplied Host PC running LinuxCNC software, with configuration files suitable to the application

FAR-25 departures from Fagor 8025 and 8030:

- Does not support sinusoidal axis input option of Fagor 8025/8030

- Inputs and outputs are not isolated

(optional buffer boards can be supplied for channel isolation)

FAR-25 should be available to some beta testers in Spring/Summer 2022. If you’re interested in updating your old Fagor controller or applying one to a different application, Contact us to discuss availability.